Dayton Water Systems specializes in advanced water treatment systems and industrial plumbing. We service all aspects of water treatment for our customers, from design and installation through aftermarket maintenance and repair. Our team can handle jobs of any size or complexity—there is no job too big or too small.

Dayton Water Systems specializes in advanced water treatment systems and industrial plumbing. We service all aspects of water treatment for our customers, from design and installation through aftermarket maintenance and repair. Our team can handle jobs of any size or complexity—there is no job too big or too small.

What is Reverse Osmosis?

In nature, weak saline solutions are attracted to stronger solvents. When separated by a semi-permeable membrane, molecules from the weaker solvent will pass through a semi-permeable membrane until the concentration of the solvent equalizes in a process known as osmosis. Real-world examples of osmosis include kidneys absorbing water from the bloodstream, plants absorbing water from soil, or the skin of our fingers absorbing water and becoming wrinkled after lengthy exposure to water.

While osmosis is a natural process, reverse osmosis (RO) requires the application of energy to the stronger saline solution, creating a pressure that exceeds the natural osmotic pressure to push the solution through a reverse osmosis membrane. A reverse osmosis membrane lets water molecules pass, but blocks the vast majority of dissolved salts, microorganisms, or other contaminants in the water. Ultimately, this removes ions and minerals from the water to create purified water.

Our Reverse Osmosis Systems

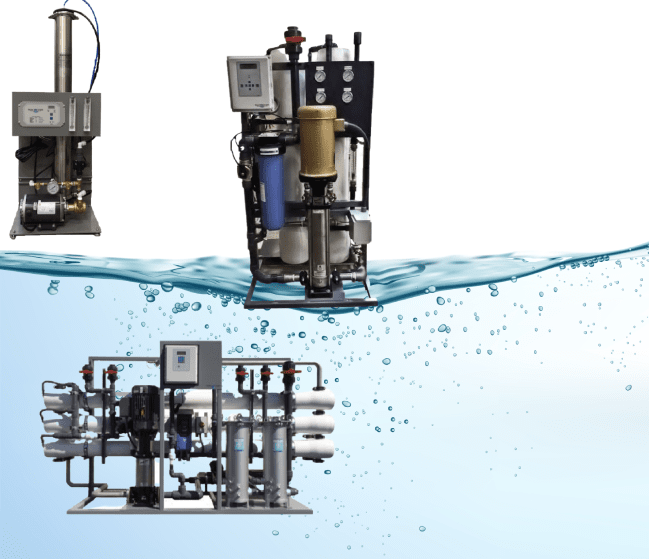

Reverse osmosis systems provide high-quality demineralized water at a mere fraction of the cost of standard deionizers. At Dayton Water Systems, our heavy-duty systems come pre-assembled and we test every unit before delivery to ensure it will function properly in its intended application. We offer the following reverse osmosis systems for commercial and industrial use.

Compact Series

Our Compact Series of RO systems are designed for low-volume applications and can treat 325–2,400 gallons per day. In testing, these models consistently featured ionic rejection higher than 98% and 33–50% recovery. With sturdy powder-coated carbon steel frames, stainless steel housing, and thin film composite membranes, our Compact Series RO units are designed and manufactured for dependability. Standard features include:

- 5 μ prefilter

- Pump with adjustable PSI

- Concentrate flowmeter

- Permeate flowmeter

- Adjustable recycle

- Liquid-filled pressure gauge

- Membrane feed

- PT interlock

- Low feed pressure shutdown

- Conductivity controller

Other optional features include stainless steel pumps and a carbon prefilter cartridge.

V8 Series

Our V8 Series RO water treatment systems can handle 11,000–66,000 gallons daily. With a powder-coated carbon steel frame, stainless steel internal pumps, FPR housing, an 8-inch thin-film composite membrane, and electronic control panel protected by a NEMA 4 enclosure, V8 Series models are built for long-term durability. With a diffuser-type design, these systems offer pulse-free, quiet operation. In testing, this line of RO treatment systems consistently delivered more than 98% ionic rejection and 50–75% recovery. Standard features of V8 Series models include:

- 5 μ prefilter

- Prefilter inlet/outlet pressure gauge

- Membrane feed/concentrate pressure gauge

- Pressure pump start delay (adjustable)

- Conductivity controller

- PT interlock

- Adjustable recycle

- Adjustable pump PSI

- Flush on idle

- Low feed pressure shut down and alarm

- Liquid-filled pressure gauges

Other optional features include:

- Permeate divert

- Clean-in-place functionality

- Auto flush

Value Series

Suitable for treatment volumes ranging between 2,400–12,000 gallons per day, our Value Series offers affordable water treatment medium-volume applications. These models feature a powder-coated carbon steel frame, stainless steel housings, and 4-inch thin-film composite membranes, offering durability and efficiency. The control panel is protected by a sturdy NEMA 4 housing and the diffuser-type design mitigates noise and ensures pulse-free operation. Standard features of our Value Series models include:

- 5 μ prefilter

- Prefilter inlet/outlet pressure gauge

- Membrane feed/concentrate pressure gauge

- Pressure pump start delay (adjustable)

- Conductivity controller

- PT interlock

- Recycle

- Adjustable pump PSI

- Flush on idle

- Low feed pressure shutdown and alarm

- Liquid-filled pressure gauges

Other optional features include:

- Permeate divert

- Clean-in-place functionality

- Recycle flowmeter

- Auto flush

- Adjustable recycle

K Series

These high-volume water treatment systems handle 66,000–198,000 gallons per day. As our most ruggedly designed and manufactured system, the K Series is designed for consistent and reliable output of demineralized water for demanding industrial applications, such as bottled water plants, boiler feeds, chemical mixing, coolant mixing, and much more. The Variable Frequency Drive (VFD) pump controller features a soft start to minimize the risk of hydraulic shock to the membrane. With a NEMA 4 enclosure over the electronic control panel, stainless steel pumps, FRP housings, and powder-coated carbon steel frame, these rugged pumps are built for long service life in harsh industrial settings.

Standard features of the K Series include:

- 5 μ duplex prefilter

- Adjustable recycle flow meter

- Pretreatment lockout

- Low feed pressure shutdown with alarm

- High prefilter Delta P indicator

- Permeate flowmeter

- Adjustable permeate divert

- High pump pressure alarm

- Membrane flush cycle

- Adjustable pressure pump start delay

- Adjustable concentrate flowmeter

- Conductivity meter and alarm

- Storage tank full indicator

- High membrane Delta P indicator

- High-pressure stainless steel piping

Other optional features include:

- Clean-in-place functionality

- pH monitor

- Acid or bisulfite feed

- BACNet remote communications

RO Water Treatment Solutions From Dayton Water Systems

Sometimes simple filtering or softening doesn’t achieve the water quality level required for critical industrial applications. Reverse osmosis units help to reduce unwanted mineral deposits in industrial process water, ensuring higher-quality mixing, rinsing, and more.

At Dayton Water Systems, we can provide standalone RO equipment or build RO capabilities into a larger water system. To see how our solutions can help improve water quality in your commercial or industrial operation, please contact us.